Furniture production process

Material purchase

Wood Process

- Particle board process

Metal Process

- Metal tube process

- Metal mesh process

- Color paint process

Product packing

Material Purchase

Purchase qualified wooden and metal materials according to the order's requirements.

Particle board process

1.Pressing and pasting color paper

The adhesive containing melamine impregnated paper is flattened on the surface of the large base particle board and pressed by a machine at high temperature.

2. Cutting

Use CNC special-shaped cutting machine and rectangular cutting machine to cut 1220mmx2440mm large particle board plain plate.

3.Sealing

Conduct edge sealing treatment on the cut particle board plate.

4.Drill

Conduct screw hole processing on the particle board after edge sealing.

5.Repair

The processed particle boards are cleaned, repaired, and colored manually or mechanically.

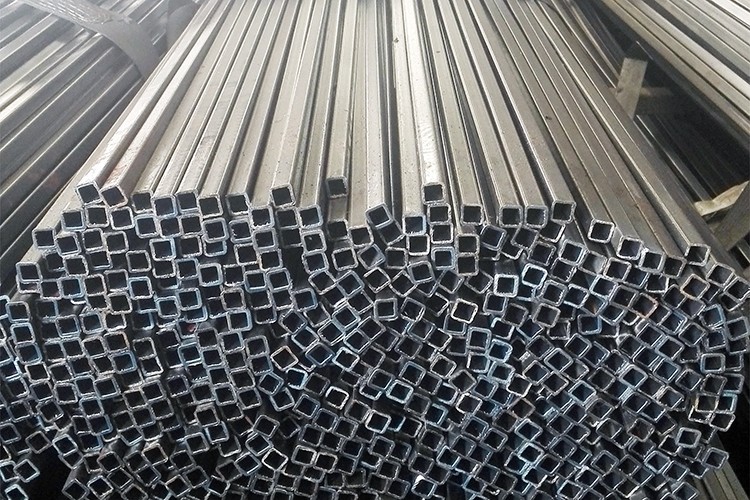

Metal Tube Process

Cutting

After inputting parameters into the laser cutting machine, the metal tube material is cut.

Punching, bending

Drill, shrink, and rotate the metal tube as required.

Welding

There are two types of welding: machine welding and manual spot welding.

Polishing

Grind the welding points of the material, and install the base nut after polishing

Paint

Finished tubes are waiting to enter the color paint process.

Metal Wire Process

The wire is mainly coiled wire, which needs to be straightened, corrugated, and cut by a straightening flying shear as required.

The cut wire is placed in a dedicated wiring mold, and the wire is butt welded using a butt welder. After the welding is completed, the remaining material is cut off, and the solder joints are polished. After completion, wait for the paint baking stage to enter.

Color Paint Process

Acid cleaning and degreasing

Put the material that needs to be painted into the pickling tank and remove the foreign matters on the surface of the material.

Clean with water

After pickling, the material is placed in a clean water tank to wash away residues such as hydrochloric acid from the surface.

Phosphating treatment

The cleaned product undergoes phosphating treatment to form a crystalline film on the surface of the product.

Air-dried baking paint

After pickling and phosphating, the material is completely dried before entering the high-temperature paint baking line.

Product packing

Pre-packed carton

Prefold the carton, pretreat with adhesive tape, and affix labels.

Place wood panel ,metal tube and accessories

Place different panels and pipes into the box after placing Poly Long or Pearl Cotton.

Finished product into warehouse

The packaged products are placed in different areas, waiting for quality inspection, sampling, and shipment.